The history of gantry tractors, also known as wide span or wide track vehicles

19th Century

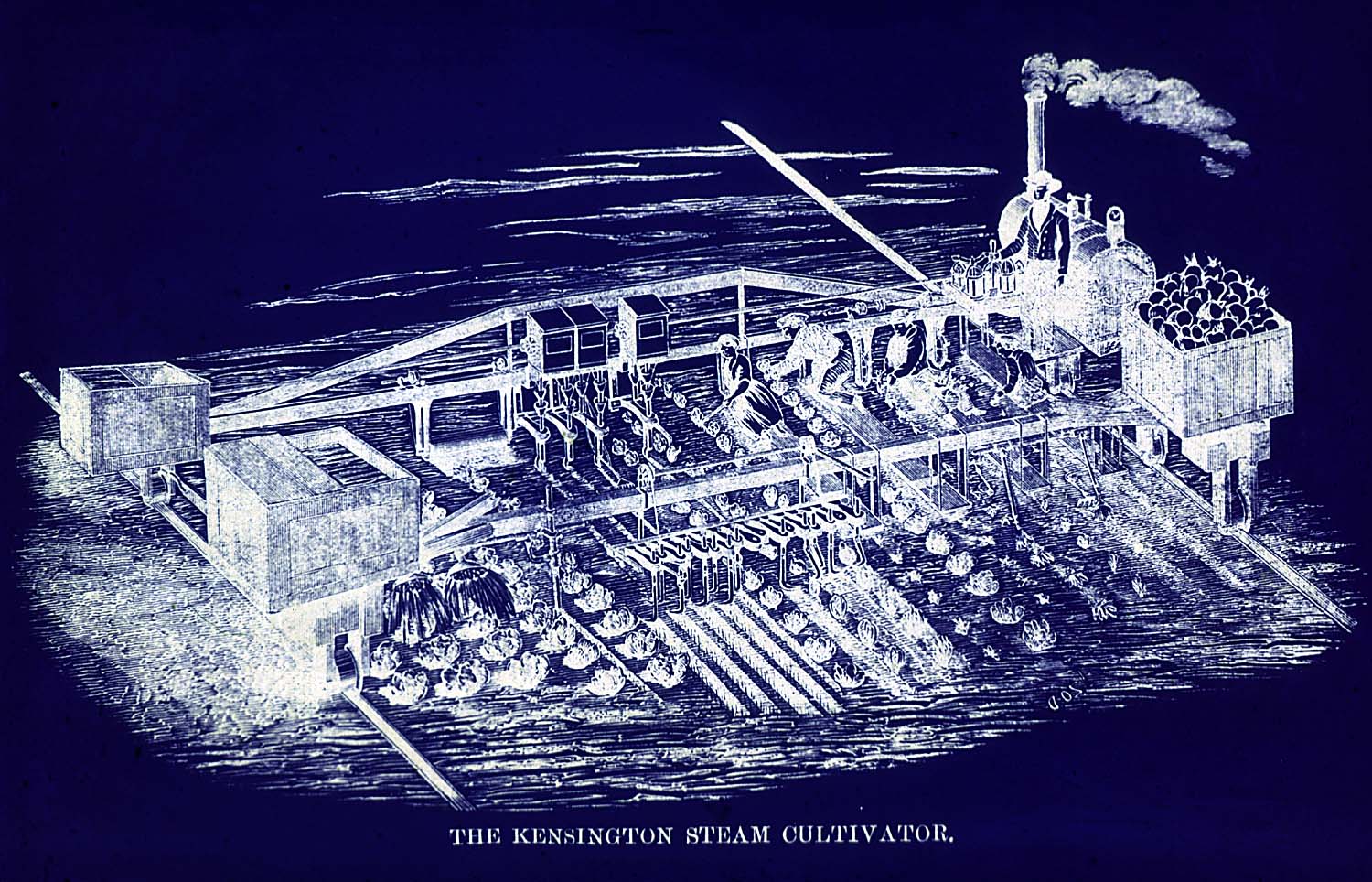

The history of gantry tractors is a surprisingly long one! The first of note appeared in the 1850s, was powered by steam and ran on rails, as illustrated alongside. The "Kensington Steam Cultivator" as it was called by its inventor, Alexander Halkett, was used on his farm in Kensington, London when this area was agricultural land and not the penthouse apartments we know today! Halkett presented a treatise to The Royal Society in 1855, titled "Guideway Agriculture" in which he described the operation of his machine. Elements of his text could easily be attributed to someone talking about "Precision Farming" in today's (2019) world, for example:

“the implements and their operation are always kept at a regulated height” and “as the seeds are sown with mechanical precision in lines, hoeing, trimming or watering can be carried out in between”.

Halkett built two such machines and seems to have used them successfully for his farming operations. Remember, this was a time when enormously heavy steam-driven traction engines were causing untold damage if they were allowed to traverse the fields. "Cable ploughing" was another way that this problem was addressed.

A more prominent engineer of the time, Henry Grafton also proposed such a machine, but this doesn't seem to have left the drawing board.

After this flurry of activity around the concept, little is evident until the 1970s, when a new approach is made.

20th Century

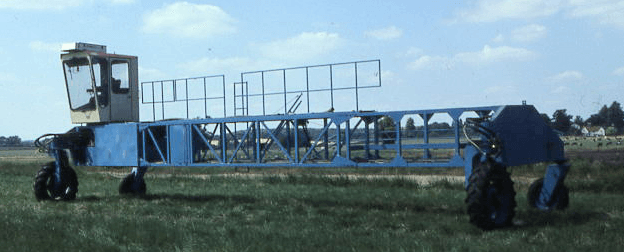

After much modification of the original "Monotrail", which was so heavy it was hardly capable of propelling itself across the field, a virtually complete farming system was developed. This included 12 m wide light cultivation, rolling and spraying and part width (enabled full width by using traversible 3-point linkages) ploughing, deeper cultivation and sowing. A 4 m wide cereal harvesting system was also developed with "miniaturised" crop separation based on 3 drums and concaves. Various illustrations of this machine are shown alongside and the video below shows it in operation across a wide range of tasks.

Video clips of the SRI gantry

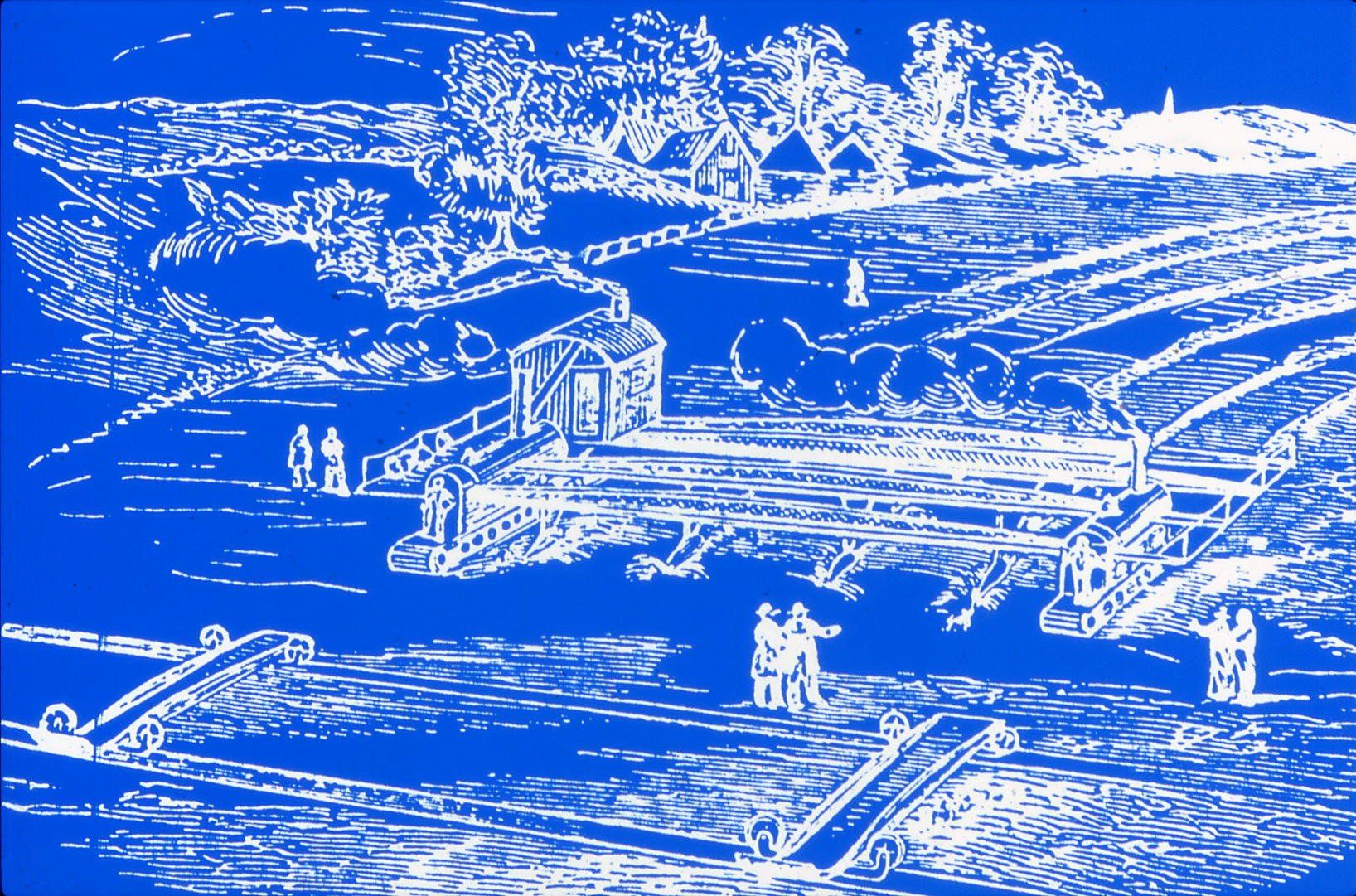

The next significant development of the gantry tractor was in the 1970s and was designed and built by David Dowler, a farmer in the Cotswolds, UK. David's name was to become synonymous with gantry tractors all around the world. Initially his machine was built to address the problem of having to spray for aphids on canola, which with traditional methods damaged about 20% of this tall crop.

His first machine was based on the transmission of a Hesston swather and spanned 12 m with an equivalent width spray boom. He soon moved on to a 24 m sprayer and a machine that could carry out light cultivation. Over the next 15 years, David rapidly developed and improved the machine to the extent that a commercial unit was introduced to the market on 1st December 1988.

David's passion for improvement didn't stop there and further significant design advances continued into the late 1990s, when more patents were filed. One thing common to all David's machines was lightness; he was correctly adamant that excessive weight would always detract from effective operation and he was proved correct many times, as was the case with a commercial offshoot in 1983. This resulted in the "Monotrail", a derivation of one of David's first machines built by Countridge. This was not a practical or commercial success, but one of the machines was bought by Silsoe Research Institute (SRI) from the receivers of the company. The Institute acquired this to further their research into a practical and efficient means of providing a complete controlled traffic farming system based on the gantry principle, and is where the story moves to next. A more complete history of David Dowler's contribution to the development of gantry systems is provided by this brief history, written in 2007 by Tim Chamen.

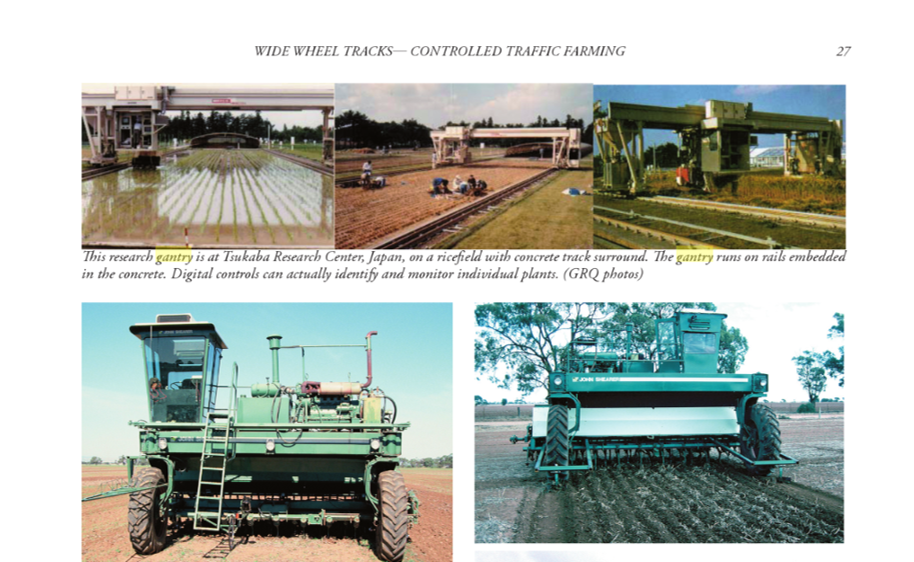

There were other developments across the world in this period, as noted by James Taylor in the book entitled ‘Soil Compaction in Crop Production’ and by Graeme Quick in the book ‘Remarkable Australian Farm Machines: Ingenuity on the Land’. The USSR and Japan were at the forefront of this, with Japan producing both 12 m and 20 m units. These ran on concrete tracks with the most recent (1987) being completely automated from the storage area to the experimental plot with robotic manipulators said to be under development.

SRI (formerly the National Institute of Agricultural Engineering) had been running experiments to determine the effects of machinery traffic on soil conditions and crop growth. The total removal of traffic from the cropped area resulted in such enormous benefits, particularly in relation to soil conditions, that they wished to pursue development of a mechanisation system that would deliver as large an area of non-trafficked soil as possible and in the most efficient and cost-effective manner. Alighting upon Halkett's invention of over 100 years prior, they considered this to be the most relevant and practical approach, particularly with modern power trains and control systems.

In parallel but completely separate from development of the gantry at the SRI at Silsoe, Ashot Ashkelon in Israel brought out their "Field Power Unit" (FPU) in the early 1980s. This was a 5.8 m span machine and was developed primarily as a tool carrier designed to reduce soil and crop damage by combining operations. Although initially not used strictly in a CTF context, it soon attracted interest from farmers in Israel. A number of commercial machines were sold in 1984 and one or two machines were demonstrated around the world.

No further machines were made and in the 1990s, most had ceased to operate. The exception was one purchased from Ashot by a UK farmer. This was shipped from Brazil to the UK together with two partially built units from Israel. The machine was very robust but also heavy and the first thing the farmer did was to change its cross-ply tyres for radials. A cultivator and drill were developed for the machine and this together with a fixed 6 m width power harrow and 29 m spray boom made up a complete crop establishment and care system. As soil conditions improved however, it became possible to direct drill in combination with just a tine cultivator. Cereal harvesting was conducted with a standard combine but on 900 mm wide tyres. This system operated for around 20 years and allowed the farm to convert from plough and power cultivation to direct sowing, as mentioned above.

There have been numerous other one-off gantry developments, including the "Avocet" designed and built by Stephen Skurray. Stephen's unit was designed primarily as a plot sprayer, capable of 12 m wide application of many different products through discrete spray lines. Differential speed at the wheels was provided by belt drives whose sprocket diameters could be adjusted by levers.

Similarly, in parallel with these developments, the Cotton Research Station at Shafter in California had a research programme that used a "Spanner" to conduct studies on trafficked and non-trafficked soil under cotton production. Lyle Carter who led the programme had to tread a fine line between the soils research and development of the wide span vehicle to keep his funders happy. Their gantry or Spanner incorporated a computer and sophisticated control systems, allowing this four-wheel-drive, four-wheel-steer vehicle to negotiate a variety of turns. As the driver's cabin was in the centre of the machine, cameras and a monitor were used to allow the driver to keep within the traffic lanes. Implements were stored on concrete "aprons" from which they could easily be coupled to a latching system beneath the spanner frame. Crop and soil responses were positive as they had been elsewhere, but there had never been any emphasis on developing the machine for a commercial market, it was merely a means to an end.

Another US develoment was at the National Soil Dynamics Laboratory in Auburn, Alabama. James Taylor of the Agricultural Research Service (ARS) designed and built a research vehicle to “manage” soil compaction (James had also designed the "Spanner" at Shafter). The 8 m wide gantry could undertake most cropping tasks, including cereal harvesting, which was achieved by mounting a conventional combine harvester on the machine.

21st Century

Further significant developments have occurred in the present century. Most prominent was the ASA-Lift 9600 wide span vehicle which was built for a controlled traffic farmer on the island of Samsø in Denmark. The principal task for which it was designed was as an onion elevator, gathering onions from a swath after they had been topped and lifted and then further elevated to a bin or bunker spanning the width of the machine. Onions were unloaded via an elevator from the tank to a transport vehicle on the headland.

The main section, which consisted of the elevators and the bin could be interchanged with another that accommodated three-point linkages on which cultivators or other implements could be mounted. Change from one mode to another could be achieved by 1-2 people and appropriate lifting gear in about an hour.

Although this vehicle achieved the tasks for which it was designed, more investment was needed to put it into scale production. A video showing it arriving and departing from fields, cultivating and onion elevating can be seen on YouTube.

In the early part of the century, a major gantry development was proposed that involved six northern European countries. The project proposed research into the cropping methods as well as the engineering design and sale of the vehicles. Assembling and formulating this multi-million Euro proposal was funded by the European Union but upon submission, it was not supported. At the core of the project was precision. This was enabled in soil terms through the introduction of wide non-trafficked beds while in vehicle terms, by its inherent stability. On the 'Present & Future' page is an illustration of the proposed crop care system which relied on sub centimetre accuracy.

Marketing of the system involved elitism and branding. Selected farmers were to be invited to take part and to lease vehicles and implements from the supplier, all of which would be maintained and serviced under contract. Products produced by the system would have unsurpassable environmental credentials and quality at affordable prices.

There have been numerous other one-off gantry developments, including the "Avocet" designed and built by Stephen Skurray. Stephen's unit was designed primarily as a plot sprayer, capable of 12 m wide application of many different products through discrete spray lines. Differential speed at the wheels was provided by belt drives whose sprocket diameters could be adjusted by levers.

Since that early part of the century, and in addition to the long established tradition of CTF in Australia, the foundation of controlled traffic systems based on conventional equipment, have been laid in the UK and other parts of Europe. Farmers are now adopting tractor-based controlled traffic systems but they have still not become mainstream so further promotional work is needed.